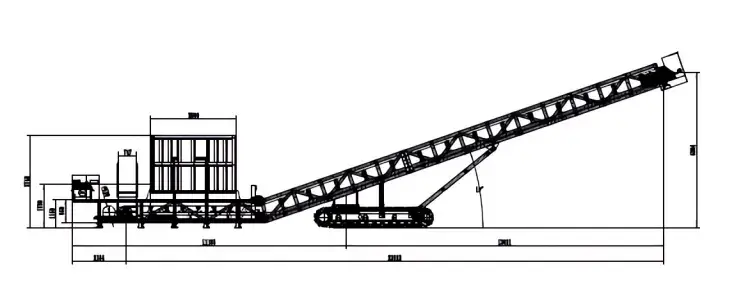

التشكيلات الأساسية والمواصا التقنية

نموذجي معدات من طراز

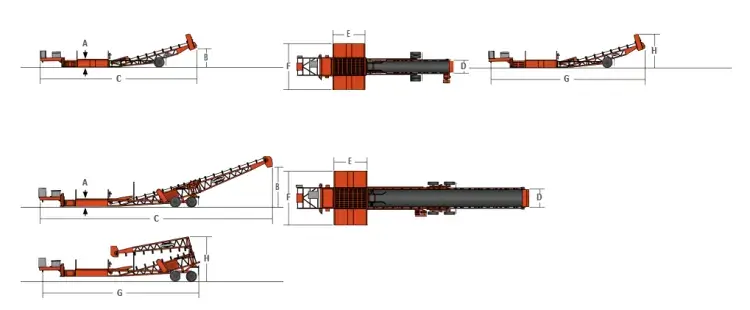

| النموذج | نوع وحدة نقل | درجة العرض | القدرة الاستيعابية | لا شيء |

|---|---|---|---|---|

| 1600 zrls-tu 1400 | الإطارات المعجلة | عيار 1400 ملم | 200-10 طن/ساعة | من خلال التحكم عن بعد، والمنحدرات الثنائية/المتوسطة الميلين والتعديل الهيدروليكي/المدوي |

| 600 1800 zrls-tu 800 | الإطارات المعجلة | 1800 ملم | 600 - 1800 طن/ساعة | من خلال التحكم عن بعد، والمنحدرات الثنائية/المتوسطة الميلين والتعديل الهيدروليكي/المدوي |

| مقدمــة مـن الجمعيـــة العامــــة | مُقَر | عيار 1400 ملم | 200-10 طن/ساعة | القابلية للتكيف في جميع المجالات، والتصميم المعدِّي للتعدين/الصنف المضاد للانزلاق |

| مقدمــة مـن الجمعيـــة العامــــة | مُقَر | 1800 ملم | 600 - 1800 طن/ساعة | عملية مستمرة، توافق مع ظروف قاسية |

تصميم العنصر الرئيسي

نظام هيكل العمل الثقيل

- الإصدارات ذات العجلات/المتتبعة: سرعة نقل الطريق البالغة 30 كيلومترا في الساعة (مدرجة بالعجلات), على التضاريس الطينية أو المنحدرة (15 درجة تدرج) (مشققة)

- هيكل الدعم الهيدروليكي: مجهز بمكابح هوائيات الهواء، ومصابيح مؤشرية ومصاعد. , رفع الرافعات الهيدروليكية.

)تابع(

- الحوافر: مدى العرض 3. 5-5. 7 متر، متوافق مع شاحنات النفاية وأجهزة التحميل والحفارات؛ مزودة بالطاقة بـ 5, 0-7. 5 كيلوواط, وحدات كهربائية/وحدات هيدروليكية.

- نظام الفرز الدوري الشامل: الشبكة المثلى للمجاميع والمعادن للحد من القطع والخسائر المادية

& &... &

- الحزام العامل ذو القوة العالية: ep100 (5+4+4 +2) إلى Pp200 (6++ 4 زائد 3), مع مفاصل ذاتية المعالجة في الموقع للعمر الممدد

- نظام رئيسي مزدوج الدفع: محركات مزدوجة 11 كيلوواط (1800 ساعة في الساعة, تيك Tefc 3/60/460 مزوّد بمقلِّلات لعجلات العقور/المعجَّز والمكابح العكسية من أجل السلامة

- براميل مغلفة بالنظير: طبول محرك ٢٠ بوصة )٥٠٨ ملم( مع حوامل هاربين, سرعة تدريج قابلة للتعديل من 1-4 متر/ث

& محرف

- :: الرصد عن بُعد للبداية/المحطة اللاسلكية والرصد الصناعي الاختياري (io)

- خيارات الطاقة الكهربائية: 380-460 و3 مراحل للإمداد بالطاقة أو مولدات ديزل مكيفة حسب الطلب (لسيناريوهات خارج الشبكة)

- الإضافات: منظفات الأحزمة، أغطية التفريغ، اسطوانات رفع الإطار الهيدروليكي وأكثر.

يكفل تصميم الوحدات النموذجية سهولة الصيانة، مع تحسين إمكانية الوصول إلى المكونات الحاسمة بنسبة 60 في المائة

الميزات الأساسية

عالية الكفاءة

- الاندماج المباشر مع شاحنات تفريغ يمكن من دورة واحدة للتفريغ 8 دقائق, تقليل الوقت الذي تستغرقه السفن المرفئية بنسبة 50٪

- :: الاستعاضة عن النقل القصير المدى في المناجم بنماذج لتفريغ الشاحنات (سلسلة الزرلد), خفض تكاليف اللوجستيات بنسبة 30 في المائة للطن الواحد

القدرة على التكيف الكامل

- مفرغات شاحنات ذات عجلات محمولة: النشر السريع في الموانئ/المنازل؛ ومحمِّل لتفريغ الشاحنات المجنزرة: التشغيل المستقر للمناجم الطينية أو مناجم الملح الساحلية, (بآلاف دولارات الولايات المتحدة)

- أحزمة مقاومة لدرجات الحرارة العالية (300 درجة مئوية) للركاز المائل الفولاذية, النماذج المعتمدة سابقاً للمناولة الكيميائية الخطرة

العمر الممدّر

- أسطوانات از, :: تخفيض معدلات الفشل بنسبة 40٪ في ظروف قاسية

- وتستغرق المفارش البزّية التي يرتدها الصولجان ما يصل إلى 6000 ساعة، مما يخفض تكاليف الصيانة بنسبة 50%.

المكنــة الاقتصادية

- محركات ترددية متغيرة توفر 25 في المائة من الطاقة؛ نظم قمع الغبار<10 mg/m³) meet EU/US environmental standards.

- مراقبة الضبط<0.5% error rate) ensures zero contamination in grain storage, compliant with FDA/CE certifications.

:: عملية مبسطة للتفريغ تُقصِّر أوقات دورة الشاحنات, التسارع في تدفق المواد, ويعزّز الإنتاجية

أولاً - عرض

| 1 ف-5(أ) | أولاً - مقدمة | القيمة |

|---|---|---|

| الموانئ | (أ) أُدمج مع حمولات السفن النقالة لسير سير العمل المؤتمت: "من تحميل الحمولة - التحميل- الحمل" | الوفورات التي تجاوزت مليوني دولار |

| الألغام/الألغام/المعارت | تغذية المداعم بصورة مباشرة، والقضاء على 20 شاحنة قصيرة | انخفاض بنسبة 30 في المائة لكل طن من التكلفة، و 3 x فترات صيانة أطول |

| )أ( | التحكم في التدفق بالدبور، 000 5 طن من الناتج اليومي | 9. 9٪ استعادة الغبار،<0.3% moisture variance |

| الصلب/المعاملات الكيميائية | نماذج ذات درجات حرارة مرتفعة عالية/نماذج مقاومة للانفجار ضد الانفجار تُعامل الخامات المبتورة والمواد الكيميائية الخطرة | (أ) السلامة التشغيلية،<30-second material切换 |

مُطالِج حلّ معرف

تقدِّم التكبير المُحدَّج دراسات استقصائية موقعية مجانية، ومحاكاة ثلاثية الأبعاد وخدمات تجريبية لتقديم حلول فعّالة من حيث التكلفة ومكيفة مع ظروف مواقعكم. , (أ) احتياجات الإنتاج والإنتاج.