ТЕХНИЧЕСКИЕ ТРЕБОВАНИЯ К ТОРМОЖЕНИЮ ЖЕНЩИН

- Диапазон размера меша: Brass sesh имеет много разных размеров, от 20 сот (большие отверстия) до 500 ячеек (очень небольшие).

- Обычные размерные мышцы: некоторые из наиболее часто используемых размеров ячеек включают 20, 30, 40, 50, 60, 80, 100, 200, и 500

- Диапазон толщины: отдельные провода, которые составляют сетку могут быть тонкой, начиная с 0, 1 мм, или толщиной, 2 мм

- Обычные толщина проволоки: типичная толщина проводов, используемых в латунных сетках составляет 0, 1 мм, 0, 15 мм, 0, 2 мм, 0, 3 мм, 0, 5 мм, 1 мм, и 2 мм

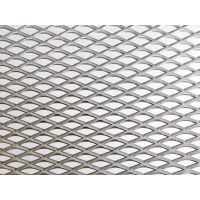

- Диапазон открытия: Размер отверстия в сетке (апертуре) изменяется в зависимости от размера ячеек. , обычно от 0, 5 мм - 3 мм

- Пример начальных размеров: например, а 20 ячеек с отверстиями около 1. , Ширина 0 мм, в то время как 100 ячеек имеют отверстия около 0, Ширина 15 мм

- Диапазон открытия: Ширина каждого отдельного отверстия в сетке также может быть охарактеризована как диапазон от 0, 05 мм - 1 мм

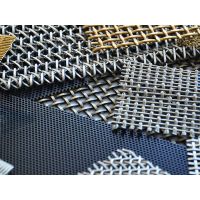

- Типы мягких: простая, стройная и голландская.

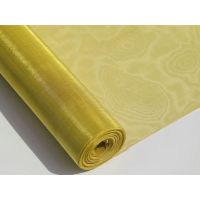

- Состав материала: проводная сетка полностью изготовлена из Брасс-Слоя, которая представляет собой смесь меди и цинка

- Стандартная поверхность Посмотрите: естественный цвет латунной сетки золотой.

- Альтернативный взгляд на поверхность: иногда, медная сетка наклеена электрошокером, чтобы придать ей другой вид или свойства

- Варианты защиты: Для предотвращения ржавчины или повреждения в сетку можно наносить такие покрытия, как лак.

- Стандартный размер листа: для листов латунных ячеек общие размеры составляют 1 метр на 2 метра (около 39 дюймов на 79 дюев), но могут быть сделаны и другие размеры

- Диапазон прокручивания: когда сетка попадает в рулон, ширина обычно составляет от 1 до 2 метров (39-79 дюймов)

- Диапазон протяженности: длина рулона латунной сетки может варьироваться довольно незначительно. , от 10 метров до 100 метров (33-328 футов)

- Измерение прочности: прочность латунной сетки (прочность на растяжение) обычно составляет от 450 до 800 Н/мм&up2; в зависимости от толщины проводов, Так и есть.